by Tommaso Cuoghi, Project Manager at EOTA

The present article delves into the evolution of EOTA's Quality Control (QC) of European Assessment Documents (EADs) in recent years. This has been my core role as Project Manager for the Organisation which I joined in 2019.

EOTA's goal in QC is to bring the quality of EADs to a rigorous and consistent level so as to provide sound assessment documents at the service of the industry and enhance the rhythm of EAD citations in the Official Journal of the European Union (OJEU).

Factors determining EAD quality

European Assessment Documents (EADs) are developed in compliance with the European Commission’s Guidelines for the EAD Format. The formal requirements included therein have been broken down into different tools for EAD writers to simplify the drafting of the documents. Among these documents are the EC Quality Checklist (an Annex to the Guidelines), EOTA's general EAD Template and specific EOTA Guidelines for individual product groups or topics.

The formal and technical quality of EADs relies on three key factors:

- Individual know-how: The EAD writers' experience and proficiency with EAD development and the before-mentioned tools lay the foundation of a sound document.

- Collective expertise: Each EAD is circulated among the working group of experts competent in the respective product areas for input (stage 4 of the EAD development process). This stage also serves as a peer review.

- Independent quality control: EOTA has implemented additional Quality Control measures (EOTA Quality Control) before the EAD is submitted to the EC Services for their review.

The initial phase of EOTA Quality Control: Formal checks

This last step was first introduced in 2019 and evolved from there.

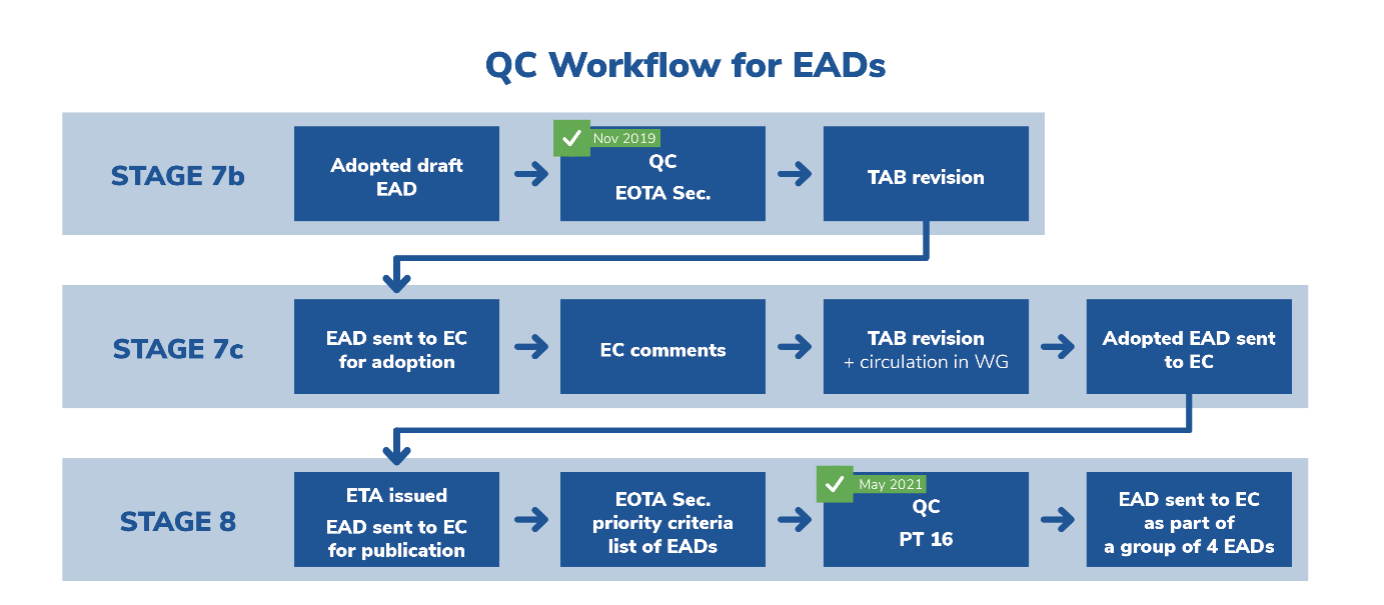

At the beginning, my role in this respect was to verify the alignment of each EAD with the formal requirements before they were submitted to the EC for observations in the adoption stage (stage 7) of the EAD development process. This check mainly involved a comparison of the EAD with the EC Guidelines, the EAD Template and EOTA's internal guidelines.

The first metric for the efficiency of this additional QC performed by the EOTA Secretariat was the amount of EC comments received during the adoption stage.

After a short while, EC comments began to decrease until they were mostly limited to technical issues, not monitored by EOTA QC at that time.

The favourable outcome of EOTA QC confirmed the added value of enhanced quality control to respond to evolving requirements and demands.

Second phase: Adding technical checks to EOTA's QC portfolio

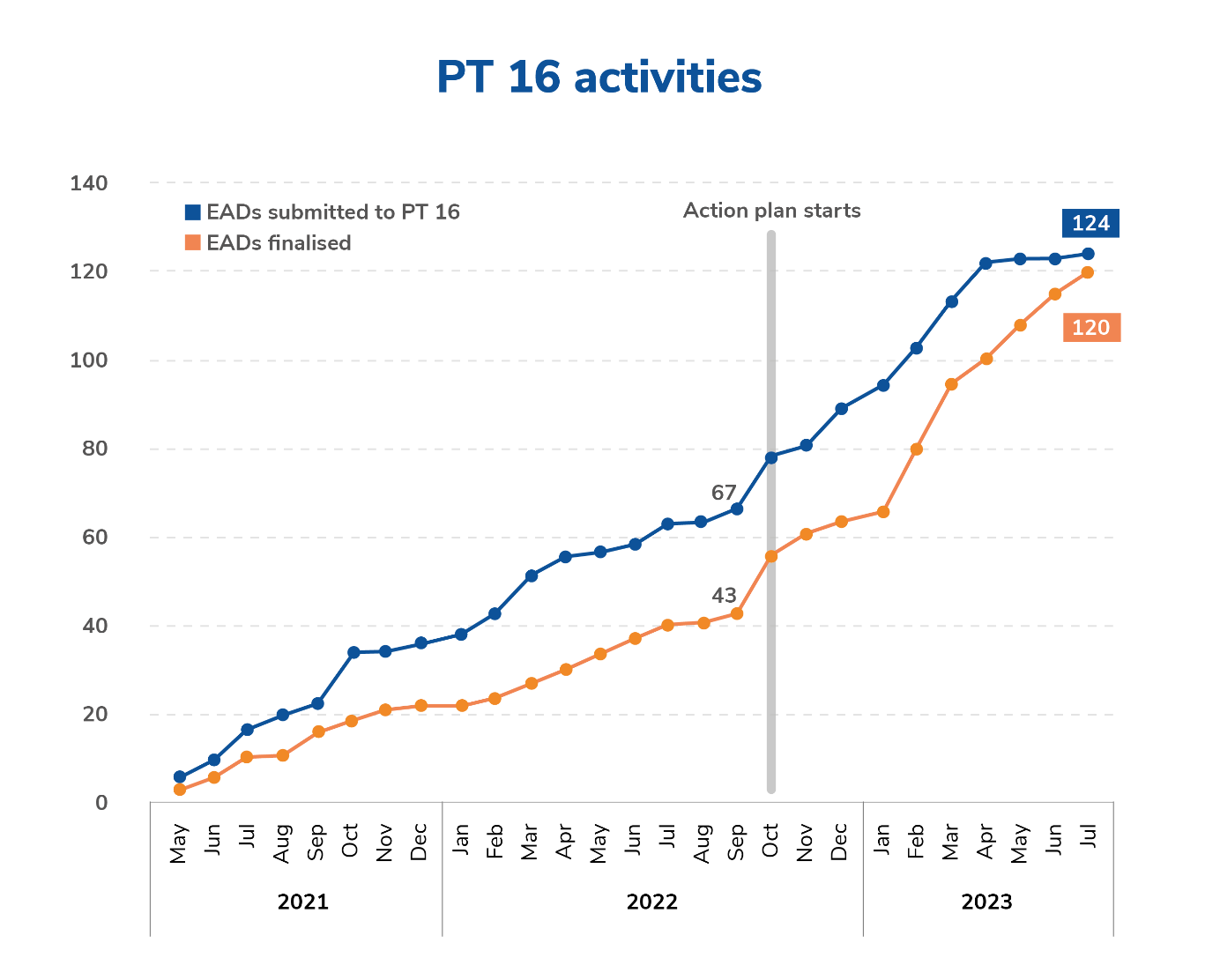

EOTA took its QC one step further in 2021 with the establishment of a dedicated Project Team (PT 16), initially composed of the Convenor plus five experts from different TABs – a number that increased to six in 2022.

The role of PT 16 experts is to review EADs pending citation in the OJEU (stage 8) before submission to the EC for their final review and greenlight.

The results of PT 16 work

PT 16 has evolved into a central component of EOTA's quality control efforts. No EAD is forwarded to the EC services for citation without having been thoroughly reviewed by PT 16. The system has also grown to be well accepted by TAB experts who receive advise and support from PT 16 experts in finalising the EAD.

The system enables EOTA to deliver enhanced EADs on a regular basis. EADs that have successfully undergone PT 16 QC meet higher levels of technical and formal quality. This facilitates the EC's revision process and mitigates the need for extensive exchanges between EOTA and the EC Services, leading to a more streamlined greenlighting of EADs for citation in the OJEU.

Furthermore, the average time required to complete a PT 16 activity – spanning from the assessment of the EAD by the PT 16 expert to the 'ready-to-send' – has significantly decreased. The increase in speed shows that EOTA has also been successful in broadening EAD-specific knowledge and know-how among TAB experts.

Outlook: Taking Quality Control one step further

EOTA envisages to take its quality control one step further in the future. The Organisation's goal is to implement QC at an earlier stage of the EAD development process with a view to lightening the final stages of the EAD development process (adoption and greenlight for citation).

Stage 4 of the EAD process – the consultation of an EAD among experts from all TABs mandated for the respective product group – has been identified as a suitable stage to implement this additional layer of QC. Implementing QC at this early stage would also allow EOTA to further and quicker spread knowledge among TAB experts. The plan would however require additional resources in terms of expert and administrative support capacities.

Conclusion

It has been four years that EOTA has systematically enhanced EAD Quality Control.

Today, EOTA can rely on a stable QC framework which enables the organisation to evaluate multiple EADs concurrently and within shorter timeframes. QC encompasses both formal and technical monitoring by a designated Project Manager at the EOTA Secretariat and experienced EAD experts from TABs (PT 16). These measures have led to a substantial enhancement in EAD quality.

Building on this foundation, the European Commission and EOTA have been successful in increasing the publication rate of EAD references in the OJEU substantially.

Moving forward, EOTA is evaluating the practicability of implementing Quality Control at an earlier stage of the EAD development process.